/prod01/university-of-lincoln-cdn-pxl/media/responsive2017/collegeofscience/nationalcentreforfoodmanufacturing/research/Reserach,Hero,Image.jpg )

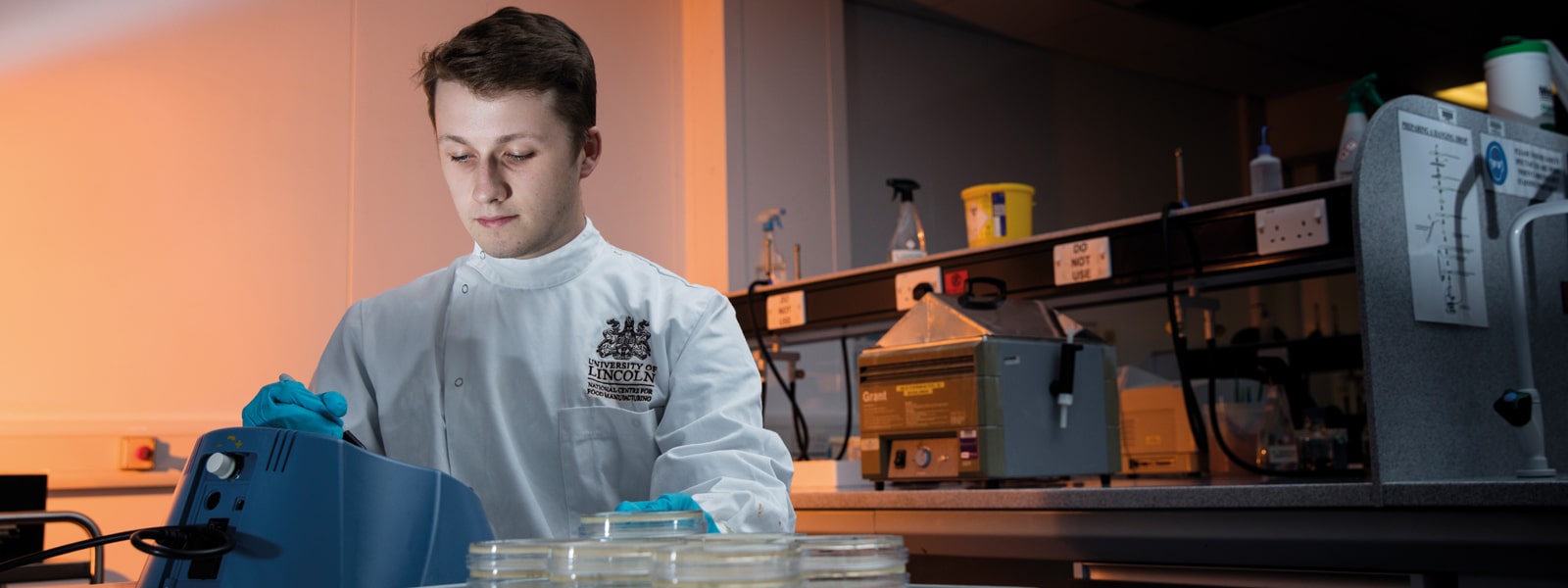

Research at the National Centre for Food Manufacturing

Transforming the Food Supply Chain

The National Centre for Food Manufacturing (NCFM) progresses high-impact, food-sector-focused research designed to advance the industry at all points in the supply chain. Current initiatives include: digitalisation of the food sector to optimise productivity and advance quality assurance; industry-focused carbon net zero and sustainability agendas; and application of analytical techniques that unlock specific challenges of food quality, safety, and nutritional performance.

NCFM has the expertise, laboratory and factory facilities, and extensive industry and academic networks, to engage at all Technology Readiness Levels (TRLs), from fundamental/basic research through to full scale commercialisation. Research is typically supported by funding sources, such as UKRI (particularly Innovate UK, EPSRC, and BBSRC), private business, and a range of EU, national, and regional funding initiatives. Projects can be specific work for one client, through to large-scale multi-partner collaborative projects. There is also a range of Master's and PhD researchers advancing food sector science and technologies.

Our Research

Study with Us

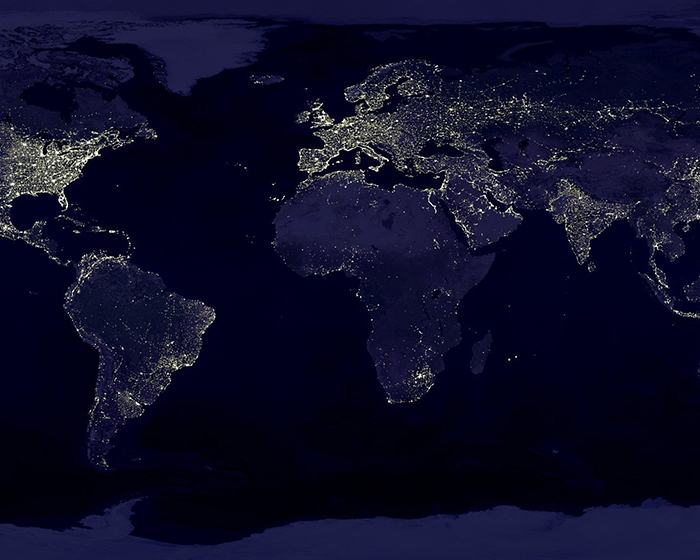

We are an internationally recognised provider of education and research in the food manufacturing and technology sector, offering a range of postgraduate programmes in food manufacturing and technology, food science, and strategic leadership.

Contact Us

The Centre of Excellence in Agri-food Technology

Holbeach

Spalding

PE12 7FJ

,Spotlight.jpg)